Beverage

Karton designs packaging solutions for the Glass and Beverage Industries, where hygiene, protection and delivery time are key to success

Glass and Beverage are industry where hygiene, protection of goods and delivery time are crucial.

Karton has taken up this challenge by designing and developing specific packaging solutions for this sector.

Working in continuous collaboration with the relevant operators, we created reliable solutions for packaging of beverages: whether glass bottles, plastic bottles, cans and related accessories, such caps and preforms, Karton is always capable to propose the ad hoc solution.

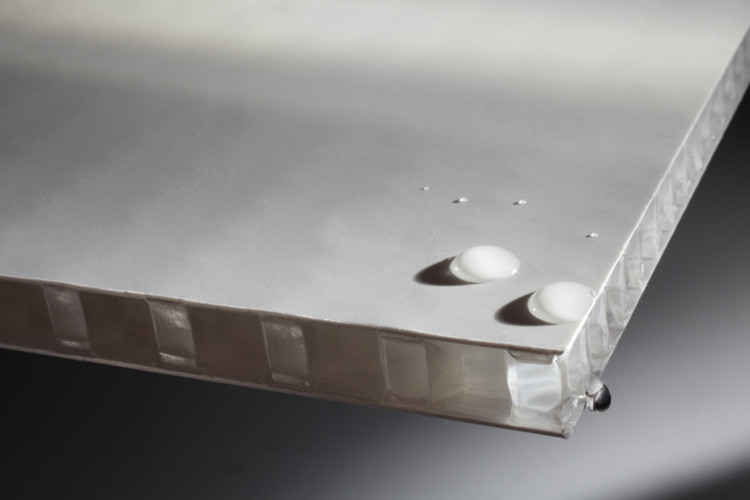

One of the most popular products in the beverage industry and a product for which Karton is renowned worldwide are the plastic divider sheets, commonly called layer pads.

In addition, we offer a wide range of complementary logistics solutions designed to facilitate the transport of bottles and cans, ensuring optimal protection and food safety: plastic pallets, slip sheets and trays as well as collapsible containers.

reusable layer pads

Widely used in the beverage industry as divider sheets in between glass or plastic bottles or cans, polypropylene layer pads enable to transport bottles or cans effectively, make palletisation easy, therefore saving packaging costs significantly.

Our layer pads are efficiently designed to meet Circular Economy's principles, with their sturdy, high-quality and reusable features. Moreover, at the end of their useful life they are 100% recyclable: they can be recycled into new products directly in our plants.

Corrugated or solid polypropylene layer pads keep your loaded pallet steady and safe during transportation.

We provide layer pads in standard pallet sizes as well as and custom sizes to order.

Our layer pads feature rounded corners to prevent tearing pallet shrink-wrap.

Several features are available: custom sizes, corner radius and custom colours.

Our layer pads feature sealed edges, to improve hygiene and ease cleaning processes.

We offer a complete range of polypropylene layer pads: those made of corrugated polypropylene (Cartonplast®) are the best sellers in the glass industry. They feature thicknesses from 2 to 12 mm and weights from 250 to 3000 g/m2.

The solid polypropylene layer pads (Eplak®) are an alternative option: in 0.8mm thickness they are particularly suitable for the transport of cans and jars, while thicknesses around 3mm are the most suitable and durable solution for the logistics of ‘heavy glass’, such as the bottles for sparkling wines. The thickest of the range is 4.2 mm, recommended for heavy-duty loads.

The newest design is a layer pad designed specifically for the logistics of glass jars for the cosmetic sector: a special surface featuring a high friction coefficient to prevent slipping during transport.

top frames and phyl pallets

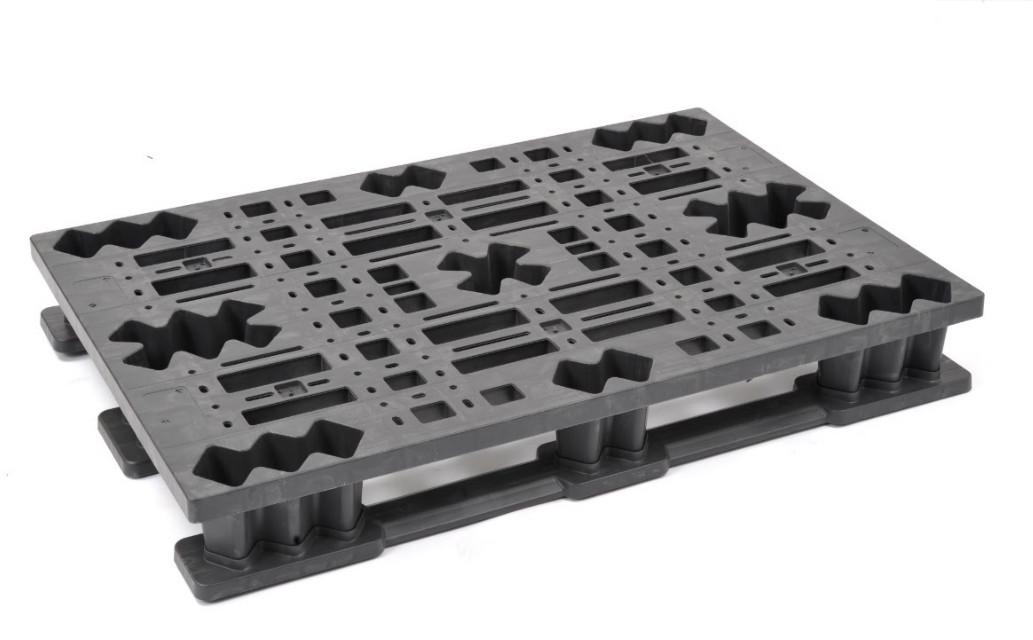

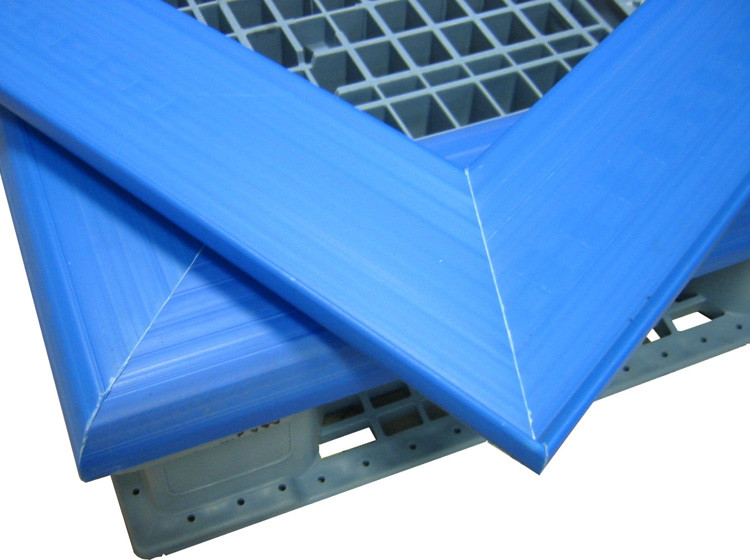

Top frames are a frame structure used to stabilise bulk container shipments of glass bottles and jars, plastic bottles as well as metal cans.

Usually combined with our layer pads and Phyl pallets, they stabilize product loads securing the different layers in a safe way.

Made of polypropylene, a highly recyclable polymer, they are designed to prevent breakage of the stretch film.

Their durability and reusability keep packaging costs down and improve transit safety.

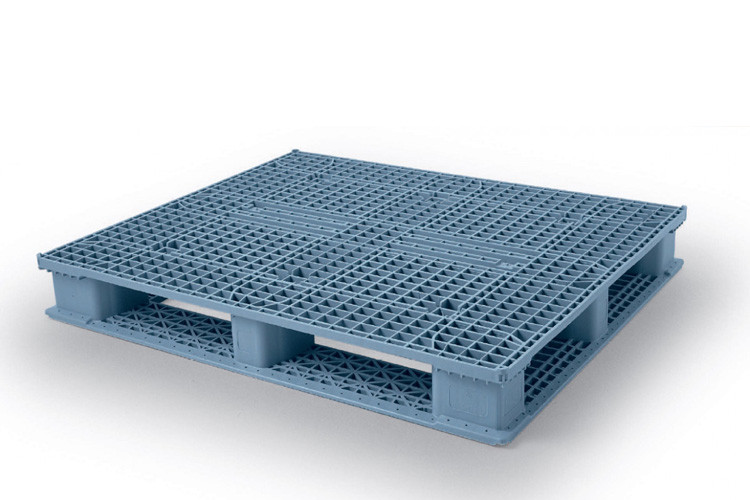

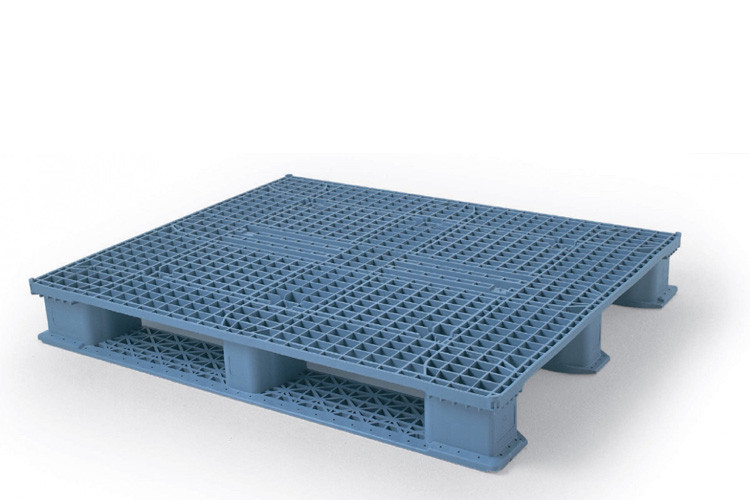

Phyl pallets are particularly suitable for the beverage business, since they cannot be attacked by any moulds, fungi or bacteria, being made of inorganic material.

Unlike wood pallets, the do not need any fumigation and they are easily washable.

They are durable: plastic pallets are almost 20 times longer lasting than traditional wooden pallets; their dimensions and shape remain unchanged over time.

Their mechanical characteristics and load resistance are tested in accordance with UNI/ISO 8611 standards.

octabins

Octabins are an environmentally friendly and cost-effective alternative to metal or woods bulk containers.

Octabins are made of a base, a foldable sleeve and a lid and they are manually erected in a few seconds.

The octagonal shape perfectly integrates in existing production lines and automated systems.

We manufacture octabins with our corrugated polypropylene signature materials: lightweight but at the same time heavy-duty.

This unique feature makes our octabin the perfect solution to decrease total weight of the load, reducing freight costs and ultimately CO2 emissions.

When empty or stored in warehouse, octabins are flat pack.

We can produce bespoke sizes as well as standard pallet sizes.

We can as well custom print on the octabin.

Robust and durable, octabins are reusable, and can be used with or without a liner.

They are easy to clean, thanks to their smooth surface.

If specially designed to carry plastic caps, we can provide octabins with a bottom dispensing opening, which is usually the preferred releasing system for bottles closures.